As you know, rivets are one of the cheapest and fastest connection methods in the world and can be used to permanently connect different parts such as (aluminum, copper, steel, etc.). Rivets have a variety and different characteristics, which are produced based on the needs of different industries in the United Rivet Company. The hammer rivet is one of the best rivet models that are used in many industries today.

Since the main dimensions of rivets include rivet diameter, rivet length, rivet head diameter, and rivet hole depth, there are many standards for rivets, for example, these standards are named (DIN, BS, ISO, etc.) It is common among the artisans of our country. All the products of Tamedeh Perech Company are produced according to global standards or according to the needs of consumers.

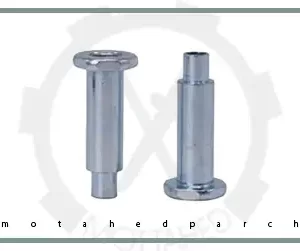

Introduction of hammer rivets

Rivets are widely used in permanent connections and there are various models for rivets. One of them is a hammer rivet. Joints made with hammer rivets are permanent and strong, and it is better to know that these joints are not easily opened. This rivet is widely used in blind and open bottom applications. You can order this type of rivets from Amadi Perech.

Where are hammer rivets used?

This type of rivet is used in construction, fiberglass roofs, hangers, wind shields, doors and windows, etc. Among other applications of hammer rivets in the construction industry, the following can be mentioned:

Hammer rivets for working with wood

Such as wooden shelves, cabinets, closets, sofas, stands, etc., in which Nir metal is used.

Automotive and aircraft manufacturing

Connections such as welding, bolts and nuts, soldering, etc. are used in the construction of vehicles.

The use of hammer rivets in the shipbuilding and submarine industry

Due to the high resistance of this hammer rivet model, it is widely used in shipbuilding and submarine industries.

Rivet selection criteria

- Rivet diameter

- rivet length

- Hollow rivets

- Solid rivets

There are no reviews yet.