motahedparch

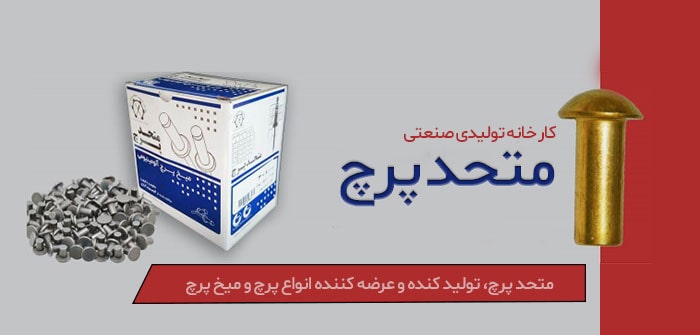

Tamedih Rivet Company is one of the old manufacturers of high quality rivets, so this factory was able to establish its second motahedparch in 2013; Today, this company is one of the best rivet manufacturers in the country.

United rivet wire tensioning services

With more than half a century of history and work experience in the field of wire tensioning, Amadih Perech operates with the aim of meeting the needs of iron wire in the industry and preventing foreign exchange. All the products of this company are manufactured according to the strictest tensile standards and with high precision in order to satisfy the customer.

The main activities of Tamideh Parech Company in the field of wire tensioning are as follows

- Wire tension with high precision and completely accurate based on customer order from size 1mm to 6.5mm.

- Ability to stretch in high tonnage by using several devices and forces.

- Equipped with a laboratory to check the stretching and hardness testing process.

United Rivet Galvanized Plating Services

Galvanized plating is one of the most common and cheapest coatings among other platings. In addition to resistance, plating is also used to increase and improve the decorative properties of parts.

Tamedeh Perech Company intends to use the best raw materials and high quality to perform plating of industrial parts and connections such as rivets and nails. Also, this company offers all kinds of color coatings on electroplating to its customers.

Introduction of Asian rivets

Rivet Asia Company is one of the companies that was established and started working in 1364 and has been able to supply all kinds of high-quality rivets, bolts and nuts to the market, which are used in aviation, automotive, industrial, etc. do These bolts and nuts are made of very resistant material and it is possible to buy them in person or offline (online).

One of the most important uses of Rivet Asia company’s rivets is to connect metal sheets in the automotive industry, especially for attaching metal sheets to the car body, as well as connecting license plates to cars.

The connection of parts using these rivets is very resistant and after riveting, two parts are difficult to separate from each other, so you have to use a special device to separate this rivet.

Rivet Asia Company is one of the reliable companies that exports thousands of tons of rivets to other countries every year.

You should note that Tamideh Rivet, in cooperation with Rivet Asia Company, which produces all types of rivets, has been able to become one of the best companies selling rivets and rivets in Iran.

This company is always ready to cooperate with automotive and aviation industries and also accepts special orders according to customers’ requests. This company has many years of experience that has made it well known in the world.

Buy rivets

As you know, when buying rivets, you should pay attention to the tensile and shear forces that are supposed to come on the work piece, and choose rivets according to their diameter, material and spacing. It is usually recommended to choose rivets that are similar in terms of material. For example, it is better to use copper rivets to connect copper sheets, and aluminum rivets are usually used to connect metal parts. We also have a type of rivet called wide head rivet which is mostly used in making school chairs.

What is a rivet?

A rivet is a very practical tool that is used to connect two pieces or several objects. When we need to permanently connect two pieces, using rivets can be very efficient.

Of course, in order to permanently connect two parts with rivets, we must pay attention to things like how to install rivets and rivet alloys.

Connections in the application of rivets

The use of riveting does not lead to joints between two metals or parts of the same material. Sometimes we may want to connect a more fragile and less resistant part (such as plastic) to metal.

or if we want to rivet a softer metal to a resistant metal, or to rivet a piece of wood to a piece of plastic or metal or the same material as wood, which is why one of the basic points for doing a Correct and principled riveting is the right choice of rivets.

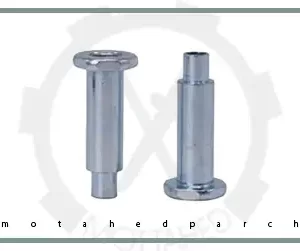

If you intend to permanently connect two pieces together, rivets can help. Rivets can be the best and fastest option for connecting two sheets together. The rivet has two parts, the nail and the body, which change according to the type of use of the rivet, the material and the shape of the nail and the body.

Introducing types of rivets

There are many types of rivets. some of which are:

Permanent rivet or solid rivet

Permanent rivets are also used for the construction of bridges and airplanes that require high strength. The head of this type of rivet is round and its body is a solid metal cylinder, and in order to create this connection, it must be turned with a hammer or a riveter tool to make the connection.

To use this type of rivet, you must have access to both sides of the rivet piece.

Semi-tubular or semi-filled rivets

This type of rivet consists of a round head with a hole in the middle. In fact, it is a cylinder that is empty inside.

Introduction of blind or hollow rivets

The blind rivet has a high installation speed and does not require access to both sides of the work piece in order to work with it. But this type of rivet is less resistant to corrosion and is not efficient for sensitive connections. The load bearing in this rivet nail model is lower than the semi-tubular model.

Aluminum or stainless rivets

This type of rivet is made of aluminum both inside and outside the body and is very useful for wet environments.

Comb rivet nail

This type of rivet is produced from steel, stainless steel, aluminum, brass or copper. This type of rivet has a flat, oval, button or sword-shaped cap on one side and a solid shoulder on the other side.

which includes a small tab or hole in some models. The speed of working with this type of rivet is high and despite the fact that it makes a strong connection, the piece can have the required rotation.

This type of rivet has great assembly power and creates a strong and permanent connection and can be a suitable alternative to threaded fasteners.

riveter

This type of rivet nail is used for soft parts, which can spread the pressure on the surface and not harm the work piece, for this reason, this type of nail is also used to connect soft materials such as foam.

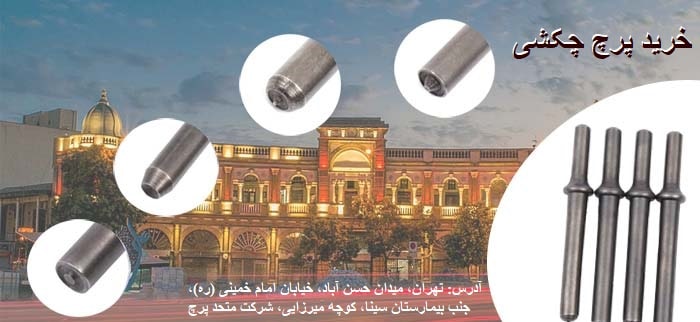

Percussion or hammer rivets

This type of rivet is used in the connections of metal sheets, profiles, shipbuilding, metal skeletons, etc., and they are used up to 36 mm in diameter.

This type of rivets are used in two ways, hot and cold. Diameters up to 10 mm are used in the cold method and 10 to 36 mm in the hot method. Series of this type of rivets can have different forms.

Rivet nail

This type of nail is used for metal sheets in car bodies and kitchen appliances. This type of rivet consists of a hollow cylinder.

Tubular rivet nail

This type of rivet is used for light metal parts or leather, artificial materials, cardboard, etc. and they are not suitable for sealing. Tubular rivets have a tubular body made of brass, copper, aluminum, or mild steel.

Investigation of fungal rivets

You can use mushroom rivets to connect thin sheets, which need to be completely smooth on one side and have no unevenness.

There are also types of nails, rivets, which are used in industries and special cases. Pope’s rivet, pin rivet, crack or explosion rivet, Schubert rivet.

How to choose the right rivet

In order to do a basic rivet work with good strength, you have to choose a suitable rivet nail. In order to choose the right rivet, you should pay attention to the following points.

How to choose the type and diameter of rivets?

The type and diameter of the rivet are among the factors that influence the strong connection of two parts. By checking the specification tables of rivets and considering tensile and shear strength, you can choose the type and diameter of rivets suitable for your work.

You should note that the length of the rivet should be about the diameter of the rivet plus the thickness of the work. For example, a rivet nail of 10 x 4 mm can be used in a workpiece with a thickness of about 6 mm.

The choice of rivets is the same as the connecting metals. For this purpose, you can use all kinds of steel rivets, copper, steel, aluminum rivets, etc. that are available in the market.

What is the type of rivet?

The material of the rivets is often made of steel, aluminum and steel, the most commonly used material is steel rivets with galvanized coating, and the material of the body of the rivets is made of steel, aluminum, copper and steel.

And the most widely used material used for the body of rivets is aluminum. Rivets have many uses in the industry, for example: It is used in the automotive industry, furniture, condos, etc.

The use of rivets in various industries

If you intend to permanently connect two pieces together, rivets can help. Rivets can be the best and fastest option for connecting two sheets together. The rivet has two parts, the nail and the body, which change according to the type of use of the rivet, the material and the shape of the nail and the body.

The use of riveting does not lead to joints between two metals or parts of the same material. Sometimes we may want to connect a more fragile and less resistant part (such as plastic) to metal.

or if we want to rivet a softer metal to a resistant metal, or to rivet a piece of wood to a piece of plastic or metal or the same material as wood, which is why one of the basic points for doing a Correct and principled riveting is the right choice of rivets.

If you intend to permanently connect two pieces together, rivets can help. Rivets can be the best and fastest option for connecting two sheets together. The rivet has two parts, the nail and the body, which change according to the type of use of the rivet, the material and the shape of the nail and the body.

Today, rivets and rivets are used in many industries, which has made the quality and resistance of rivets very important; In the following, we have reviewed some of the uses of rivets.

The use of rivets in the automotive industry

As you know, rivets have many applications in various industries, and one of them is in the automotive industry. Rivets usually have many applications in the connection of thin metal sheets, which in automotive industry focuses on attaching the license plate to the car body. When they attach the car license plate to the car body with rivets, it is difficult to remove it and they need special devices to remove it.

Colored rivet fittings

Colored rivet nails are the same as normal rivets, but with colored heads, you should note that these rivets are available in different colors in United Rivet Store. Etisalat’s colored rivet nails are used in all kinds of component connections such as aluminum, steel, copper, stainless steel, etc. It also has different sizes that you should choose according to the project you have. Big, small, thick and thin diameter depends on your application. Etisalat colored rivets are usually used when they want to add some beauty to the project. Colored rivets are available in yellow, blue, red, green, orange, brown, etc. colors.

The use of colored rivets in different industries

Colored rivets are the simple nails whose body and head are colored and are considered to be very beautiful and special rivets. Colored rivets are usually used in cases where the rivet connection is exposed and the final product must maintain its beautiful appearance despite these feathers.

The use of colored rivets can be used to connect parts such as aluminum, steel, stainless steel, etc. This rivet model also has many different sizes, which makes it possible to use them in very delicate works or in industries that produce industrial parts.

You can use colored rivets for decorative works that you want to be very beautiful. Colored rivets have different colors, the choice of which color depends on your taste.

One of the prominent features of these rivets is their very high resistance to wear and corrosion and other factors, and they also have great beauty. As mentioned, this model of rivets is produced in different colors, which are usually used in decorative industries.

half hole rivet

There are different types of rivets, one of which is a half-hole rivet. To use this model, you can use a manual riveter, which is very light and can be used easily, but to use rivets in large industries, it is better to use an air or pneumatic riveter because this device works It makes you easy and fast.

A half-hole rivet has a round head and a nail with a hole in the middle of the nail. In general, it can be said that it is a cylinder with an empty middle. Rivets are used to connect two pieces to each other permanently.

Buy half-hole rivets

Application and how to use the half-hole rivet

The way to use a half-hole rivet is that you have to put the rivet nail in the hole and do the riveting operation with the riveter. In order for your riveting operation to be done well, you must follow a series of points:

- The parts that are connected to each other must be completely close to each other and then the riveting operation is done.

- If you have a problem during riveting, adjust the device and choose the right pacifier head to solve the problem.

- You need to put the riveter perpendicular to the workpiece and press the nipple together with the tool.

- If the part you want to connect to another is non-metallic, you must use an aluminum rivet. If the device you want to connect to another has a soft back, you can use a washer on the back of your work to prevent the rivet from sinking in. Prevent the work piece.

- When you want to connect two copper sheets together, you must use copper rivets. It is not suitable to use painted aluminum rivets to connect copper sheets.

- When connecting, be careful not to tear off the head of the rivet. If the head of the rivet is torn off, for any reason, you will not be able to perform the riveting operation correctly and the rivet will not be able to withstand the connection properly.

Types of half-hole rivets

Below we have mentioned the types of half-hole type rivets and we have provided explanations about each one:

Half-hole rivets for brake pads and clutch pads

Half-hole rivets for brake pads and clutch pads are among the mechanical fasteners, which are made of low carbon steel, aluminum, and copper, with nominal diameters of 3, 4, 5, 6, 8, 10 mm. are also available.

Introduction of half-hole rivet head lens

This type of piece has a lens-like head with a hole in the middle and looks like a cylinder that is empty inside, and they are available in the market in many sizes and often made of aluminum.

A half-filled rivet on the head of the treasury

This rivet is used for the strong connection of machine parts, which can also be separated, and the steel conical pin in many grades such as: 8/8, 10/9, 12/9 and with galvanized coating (cold, hot, dichromate) and stainless steel A2(304) and A4(316) etc. are produced.

Important points about riveting

You should note that there are many points that are very important to pay attention to when riveting, a few of these points are described in detail below:

Hole diameter for riveting

As you know, for riveting, a hole is needed in the piece. If this hole is too small, the rivet cannot pass through it. Also, if the rider is too big, it will cause it to loosen and pop out of the joint, which means that the joint was not successful. The rivet hole should be more than 0.1 mm in diameter. Note that during riveting, the diameter of the nail slightly increases and completely covers the empty space.

Introduction of riveter and how to use it

The riveter is a device that rivets the nail into the hole of the workpiece. Usually, the models of this device have a replaceable teat. There are usually several nipples of different sizes on the riveter that can be changed. It is better to know that before starting riveting, the work pieces should be placed as close to each other as possible, and then the pieces should be firmly connected to each other. It is also better to know that the riveter should be used in such a way that it is placed vertically on the work piece and its nipple is stuck on the work piece.

Riveters, like rivets, have different types and models, and the type of construction and model have different functions according to the type of riveter, for example, the riveter may be manual or pneumatic.

The best method for riveting

As you know, a tool or a device has been developed for each type of work, and for riveting, the best method is to use a variety of riveting machines or nailing machines. These devices have different types and models, the best of which is the manual riveter, because it is light and can be done with one hand. It is also better to know that for heavy projects, it is recommended to use an air or pneumatic riveting machine, because it has a convenient interface and a high speed of work; But it is still suggested that you choose the type of riveter yourself. Riveting machines have different prices compared to the work they do, for example, for simple jobs that use a manual riveter, it has a lower price than an air or pneumatic riveting machine, because the pneumatic riveting machine has a functional interface. It is simple and fast, but the hand riveter is used for simple tasks and short-term projects. Of course, it goes without saying that in some situations you have to consider the type of rivet, but in general, don’t worry too much because there are suitable nozzles on the riveter that can be used.

Advantages of riveting

Riveting has many advantages over other connection methods. Some of these advantages are as follows:

- Riveting operation is a cost-effective method.

- From riveting in the joints of ferrous and non-ferrous metals such as aluminum and copper and in the joints of non-metallic materials such as: Wood, plastic, asbestos sheets, etc. are widely used.

- One of the main advantages of riveting is to connect dissimilar parts to each other. As: Connecting an aluminum plate to a copper plate.

- The ability to connect regardless of the location of the parts (vertical, overhead, etc.)

- Riveting is very environmentally friendly. Because unlike the welding process, it does not produce smoke or gas.

- Riveted joints are compared to other methods in cases where the joint is subjected to excessive pressure and vibration.

- Riveting operation has high shear resistance and fatigue.

- Aluminum rivets are lighter than bolts. They are also highly resistant to chemical corrosion.

- Since there is no metal melting and heating and cooling in the joining process, thermal effects on riveted joints are minimal. As a result of the material’s protective coatings, no damage is caused.

- It is easier to check the quality of the riveted joint than to check the weld.

- Removing a riveted joint causes less damage than a welded joint.

Important tips for using rivets

It is very important that you know how to rivet and use the right tools. Also, in order not to spend a lot of money on riveting, be sure to pay attention to the type of rivets you choose. As mentioned, the following list is the points that you should follow in riveting.

- The right choice of rivets

- Determine the diameter of the hole for the rivet

- Riveting method

- The workpiece to be connected with rivets

Video introduction of all kinds of rivet products

In the following video, you can see the types of rivet models and learn about them:

Frequently asked questions about buying rivets

Aluminum rivets are usually used to connect metals.

Usually, the rivet hole should have a diameter greater than 0.1.

You can buy rivets online for a comfortable and safe purchase, you should note that currently Tamideh Perch has a lot of experience in the field of producing and selling all kinds of rivets and provides high-quality products to people.

Rivets are used in various industries and are mostly used to connect metal sheets to the work piece. One of the industries where rivets are present is the automobile industry, which is used to connect the license plate to the car body.

Asia Rivet is one of the best manufacturers of rivets, nuts and washers in Iran, which exports a lot abroad due to its popularity and produces more than 5 thousand tons of products annually.

Like other simple rivets, colored rivets are usually used to beautify the project, which are available in different colors such as yellow, blue, red, green, orange, brown, etc.